(Ph. Eur. monograph 0838)

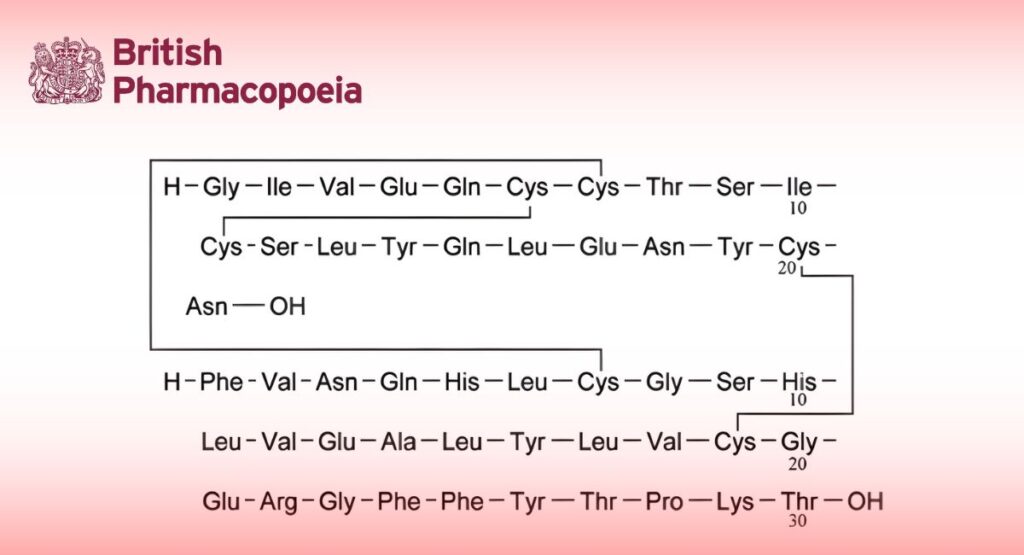

C257H383N65O77S6 5808

Action and use

Hormone; treatment of diabetes mellitus.

Preparation

Insulin Preparations

DEFINITION

Human insulin is a 2-chain peptide having the structure of the antidiabetic hormone produced by the human pancreas.

Content

95.0 per cent to 105.0 per cent of human insulin C257H383N65O77S6 plus A21 desamido human insulin (dried substance).

By convention, for the purpose of labelling insulin preparations, 0.0347 mg of human insulin is equivalent to 1 IU of insulin.

PRODUCTION

Human insulin is produced either by enzymatic modification and suitable purification of insulin obtained from the pancreas of the pig or by a method based on recombinant DNA (rDNA) technology.

Where applicable, the animals from which human insulin is derived must fulfil the requirements for the health of animals suitable for human consumption.

Human insulin is produced under conditions designed to minimise the degree of microbial contamination.

For human insulin produced by enzymatic modification of insulin obtained from the pancreas of the pig, the manufacturing process is validated to demonstrate removal of any residual proteolytic activity.

The competent authority may require additional tests.

For human insulin produced by a method based on rDNA technology, prior to release the following tests are carried out on each batch of human insulin, unless exemption has been granted by the competent authority.

Host-cell-derived proteins

The limit is approved by the competent authority.

Single chain precursor

The limit is approved by the competent authority. Use a suitably sensitive method.

CHARACTERS

Appearance

White or almost white powder.

Solubility

Practically insoluble in water and in ethanol (96 per cent). It dissolves in dilute mineral acids and with decomposition in dilute solutions of alkali hydroxides.

IDENTIFICATION

A. Examine the chromatograms obtained in the assay.

Results: The principal peak in the chromatogram obtained with the test solution is similar in retention time to the principal peak in the chromatogram obtained with reference solution (a).

B. Peptide mapping (2.2.55).

SELECTIVE CLEAVAGE OF THE PEPTIDE BONDS

Test solution Prepare a 2.0 mg/mL solution of the substance to be examined in 0.01 M hydrochloric acid and transfer 500 μL of this solution to a clean tube. Add 2.0 mL of HEPES buffer solution pH 7.5 R and 400 μL of a 1 mg/mL solution of Staphylococcus aureus strain V8 protease, type XVII-B R. Cap the tube and incubate at 25 °C for 6 h. Stop the reaction by

adding 2.9 mL of sulfate buffer solution pH 2.0 R.

Reference solution Prepare at the same time and in the same manner as for the test solution but using human insulin CRS instead of the substance to be examined.

CHROMATOGRAPHIC SEPARATION. Liquid chromatography (2.2.29).

Column:

— size: l = 0.10 m, Ø = 4.6 mm;

— stationary phase: octadecylsilyl silica gel for chromatography R (3 μm) with a pore size of 8 nm;

— temperature: 40 °C.

Mobile phase:

— mobile phase A: mix 100 mL of acetonitrile for chromatography R, 200 mL of sulfate buffer solution pH 2.0 R and 700 mL of water R; filter and degas;

— mobile phase B: mix 200 mL of sulfate buffer solution pH 2.0 R, 400 mL of acetonitrile for chromatography R and 400 mL of water R; filter and degas;

| Time

(min) |

Mobile phase A

(per cent V/V) |

Mobile phase B

(per cent V/V) |

| 0 – 60 | 90 → 30 | 10 → 70 |

| 60 – 65 | 30 → 0 | 70 → 100 |

| 65 – 70 | 0 | 100 |

Flow rate: 1 mL/min.

Detection: Spectrophotometer at 214 nm.

Equilibration: At initial conditions for at least 15 min. Carry out a blank run using the above-mentioned gradient.

Injection: 50 μL.

System suitability:

— the chromatogram obtained with the reference solution is qualitatively similar to the chromatogram of human insulin digest supplied with human insulin CRS;

— in the chromatogram obtained with the reference solution, identify the peaks due to digest fragments I, II and III; symmetry factor Maximum 1.5 for the peaks due to fragments II and III; resolution Minimum 3.4 between the peaks due to fragments II and III;

Results: The profile of the chromatogram obtained with the test solution corresponds to that of the chromatogram obtained with the reference solution.

NOTE: the retention time of fragment I is the same for porcine insulin and for human insulin. The retention times of fragments II and IV are the same for all insulins. The retention time of fragment III is the same for bovine insulin and for porcine insulin.

TESTS

Impurities with molecular masses greater than that of insulin

Size-exclusion chromatography (2.2.30): use the normalisation procedure.

Test solution: Prepare a solution containing 4 mg/mL of the substance to be examined in 0.01 M hydrochloric acid.

Resolution solution: Use a solution of insulin (about 4 mg/mL), containing more than 0.4 per cent of high molecular mass proteins. An injectable insulin preparation, whether a solution or a suspension, that has been clarified with a sufficient amount of 6 M hydrochloric acid R, containing the indicated percentage of high molecular mass proteins, or a solution prepared from insulin, dissolved in 0.01 M hydrochloric acid, may be used. Insulin containing the indicated percentage of high molecular mass proteins may be prepared by allowing insulin powder to stand at room temperature for about 10 days.

Maintain the solutions at 2-8 °C and use within 7 days. If an automatic injector is used, maintain the temperature at 2-8 °C.

Column:

— size: l = 0.3 m, Ø = minimum 7.5 mm;

— stationary phase: hydrophilic silica gel for chromatography R (5-10 μm) with a pore size of 12-12.5 nm, of a grade suitable for the separation of insulin monomer from dimer and polymers.

Mobile phase: Mix 15 volumes of glacial acetic acid R, 20 volumes of acetonitrile R and 65 volumes of a 1.0 g/L solution of arginine R; filter and degas.

Flow rate 0.5 mL/min.

Detection: Spectrophotometer at 276 nm.

Equilibration: Before using a new column for chromatographic analysis, equilibrate by repeated injections of an insulin solution containing high molecular mass proteins. This can be done by at least 3 injections of the resolution solution. The column is equilibrated when repeatable results are obtained from 2 subsequent injections.

Injection 100 μL.

Run time About 35 min.

Retention time: Polymeric insulin complexes = 13-17 min; covalent insulin dimer = about 17.5 min; insulin monomer = about 20 min; salts = about 22 min.

System suitability: Resolution solution:

— peak-to-valley ratio: minimum 2.0, where Hp = height above the baseline of the peak due to the dimer and Hv = height above the baseline of the lowest point of the curve separating this peak from the peak due to the monomer.

Limits: The sum of the areas of any peaks with a retention time less than that of the principal peak is not greater than 1.0 per cent of the total area of the peaks. Disregard any peak with a retention time greater than that of the peak due to insulin.

Related proteins

Liquid chromatography (2.2.29) as described under Assay, following the elution conditions as described below:

| Time

(min) |

Mobile phase A

(per cent V/V) |

Mobile phase B

(per cent V/V) |

| 0 – 30 | 42 | 58 |

| 30 – 44 | 42 → 11 | 58 → 89 |

| 65 – 70 | 11 | 89 |

Maintain the solutions at 2-8 °C and use within 24 h. Perform a system suitability test (resolution, linearity) as described in the assay. If necessary, the relative proportions of the mobile phases may be adjusted to ensure complete elution of A21 desamido porcine insulin before commencement of the gradient. The profile of the gradient may also be adjusted to ensure complete elution of all insulin related impurities.

Inject 20 μL of reference solution (a), 20 μL of reference solution (b), 20 μL of reference solution (c) and 20 μL of the test solution. If necessary, adjust the injection volume to a volume between 10 μL and 20 μL in accordance with the results obtained in the test for linearity as described in the assay. Record the chromatograms for approximately 50 min. In the chromatogram obtained with reference solution (a), A21 desamido human insulin appears as a small peak after the principal peak and has a retention time of about 1.3 relative to the principal peak. In the chromatogram obtained with the test solution, the area of the peak due to A21 desamido human insulin is not greater than 2.0 per cent of the total area of the peaks; the sum of the areas of all peaks, apart from those due to human insulin and that due to A21 desamido human insulin, is not greater than 2.0 per cent of the total area of the peaks. For semi-synthetic human insulin only: in the chromatogram obtained with the test solution, the area of any peak corresponding to the peak due to porcine insulin in the chromatogram obtained with reference solution (c) is not greater than 1.0 per cent of the total area of the peaks.

The following test applies only to human insulin produced by enzymatic modification of porcine insulin.

Proinsulin-like immunoreactivity (PLI)

Maximum 10 ppm, calculated with reference to the dried substance and determined by a suitably sensitive immunochemical method (2.7.1) such as radio-immunoassay. Use the International Reference Reagent for porcine proinsulin to calibrate the method.

Zinc

Maximum 1.0 per cent (dried substance).

Atomic absorption spectrometry (2.2.23, Method I).

Test solution: Dissolve 50.0 mg of the substance to be examined in 0.01 M hydrochloric acid and dilute to 25.0 mL with the same acid. Dilute if necessary to a suitable concentration (for example, 0.4-1.6 μg of Zn per millilitre) with 0.01 M hydrochloric acid.

Reference solutions: Use solutions containing 0.40 μg, 0.80 μg, 1.00 μg, 1.20 μg and 1.60 μg of Zn per millilitre, freshly prepared by diluting zinc standard solution (5 mg/mL Zn) R with 0.01 M hydrochloric acid.

Source: Zinc hollow-cathode lamp.

Wavelength: 213.9 nm.

Atomisation device: Air-acetylene flame of suitable composition (for example, 11 L of air and 2 L of acetylene per minute).

Loss on drying (2.2.32)

Maximum 10.0 per cent, determined on 0.200 g by drying in an oven at 105 °C for 24 h.

Sulfated ash (2.4.14)

Maximum 2.5 per cent, determined on 0.200 g (dried substance).

Bacterial endotoxins (2.6.14)

Less than 10 IU/mg, if intended for use in the manufacture of parenteral preparations without a further appropriate procedure for removal of bacterial endotoxins.

ASSAY

Liquid chromatography (2.2.29).

Test solution: Dissolve 40.0 mg of the substance to be examined in 0.01 M hydrochloric acid and dilute to 10.0 mL with the same solvent.

Reference solution (a): Dissolve the contents of a vial of human insulin CRS in 0.01 M hydrochloric acid to obtain a concentration of 4.0 mg/mL.

Reference solution (b): Dissolve the contents of a vial of insulin porcine for system suitability CRS in 0.01 M hydrochloric acid to obtain a concentration of 4 mg/mL.

Reference solution (c): Dilute 1.0 mL of reference solution (b) to 50.0 mL with 0.01 M hydrochloric acid. To 1.0 mL of this solution add 1.0 mL of reference solution (a).

Reference solution (d): Dilute 1.0 mL of reference solution (a) to 10.0 mL with 0.01 M hydrochloric acid.

Resolution solution: Mix 1.0 mL of reference solution (a) and 1.0 mL of reference solution (b).

Maintain the solutions at 2-8 °C and use within 48 h. If an automatic injector is used, maintain at 2-8 °C.

Column:

— size: l = 0.25, Ø = 4.6 mm;

— stationary phase: octadecylsilyl silica gel for chromatography R (5 μm);

— temperature: 40 °C.

Mobile phase: Mix 42 volumes of mobile phase A and 58 volumes of mobile phase B, adjusting the composition of the mixture if necessary.

Prepare and maintain the following solutions at a temperature of at least 20 °C:

— mobile phase A: dissolve 28.4 g of anhydrous sodium sulfate R in water R and dilute to 1000 mL with the same solvent; add 2.7 mL of phosphoric acid R; adjust to pH 2.3, if necessary, with ethanolamine R; filter and degas;

— mobile phase B: mix 550 mL of mobile phase A with 450 mL of acetonitrile R. Warm the solution to a temperature of at least 20 °C in order to avoid precipitation (mixing of mobile phase A with acetonitrile is endothermic); filter and degas.

Flow rate: 1 mL/min.

Detection: Spectrophotometer at 214 nm.

System suitability:

— resolution: inject 20 μL of the resolution solution and 20 μL of reference solution (b). Record the chromatogram of the resolution solution until the peak corresponding to the principal peak in the chromatogram obtained with reference solution (b) is clearly visible. In the chromatogram obtained with the resolution solution, identify the peaks due to porcine insulin and human insulin. The test is not valid unless the resolution between the peaks due to human insulin and porcine insulin is at least 1.2. If necessary, adjust the concentration of acetonitrile in the mobile phase until this resolution is achieved.

— linearity: inject 20 μL each of reference solutions (a) and (d). The test is not valid unless the area of the principal peak in the chromatogram obtained with reference solution (a) is 10 ± 0.5 times the area of the principal peak in the chromatogram obtained with reference solution (d). If this test fails, adjust the injection volume to between 10 μL and 20 μL, in order that the responses are within the linearity range of the detector.

Injection: 20 μL of the test solution and reference solution (a).

Calculate the content of human insulin C257H383N65O77S6 plus A21 desamido human insulin using the areas of the corresponding peaks in the chromatograms obtained with the test solution and reference solution (a) and the declared content of human insulin plus A21 desamido human insulin in human insulin CRS.

STORAGE

In an airtight container, protected from light, at -18 °C or below, until released by the manufacturer. When thawed, insulin is stored at 5 ± 3 °C and used for manufacturing preparations within a short period of time. To avoid absorption of humidity from the air during weighing, the insulin must be at room temperature.

LABELLING

The label states whether the substance is produced by enzymatic modification of porcine insulin or by rDNA technology.