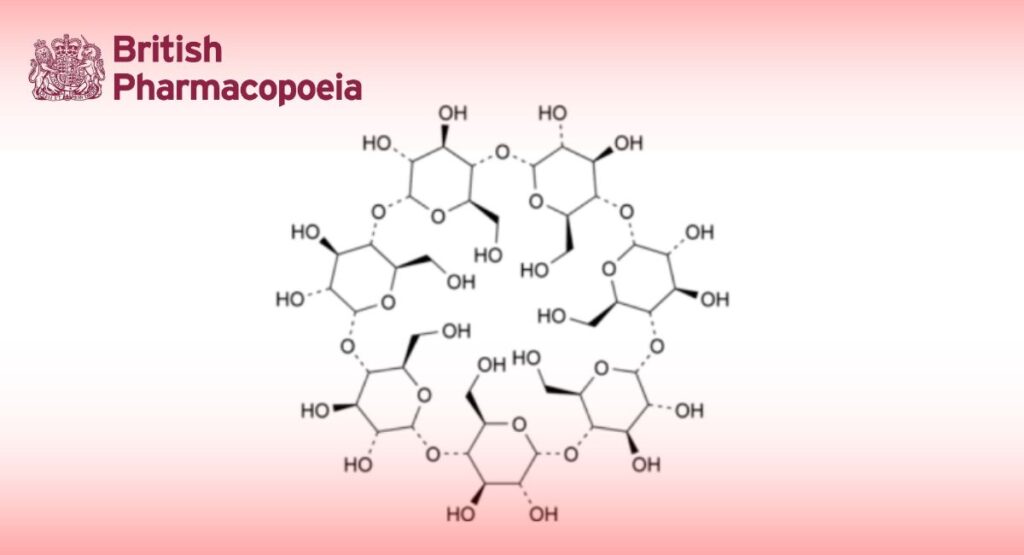

Betacyclodextrin

(Ph. Eur. monograph 1070)

[C6H10O5]7 1135 7585-39-9Action and use

Carrier molecule for drug delivery systems.

DEFINITION

Cycloheptakis-(1→4)-(α-D-glucopyranosyl) (cyclomaltoheptaose, β-cyclodextrin).

Content

98.0 per cent to 102.0 per cent (dried substance).

CHARACTERS

Appearance

White or almost white, amorphous or crystalline, hygroscopic powder.

Solubility

Sparingly soluble in water and in propylene glycol, practically insoluble in anhydrous ethanol and in methylene chloride.

IDENTIFICATION

A. Specific optical rotation (2.2.7): + 160 to + 164 (dried substance), determined on solution S (see Tests).

B. Examine the chromatograms obtained in the assay.

Results The principal peak in the chromatogram obtained with test solution (b) is similar in retention time and size to the principal peak in the chromatogram obtained with reference solution (c).

C. Dissolve 0.2 g in 2 mL of iodine solution R4 by warming on a water-bath, and allow to stand at room temperature. A yellowish-brown precipitate is formed.

TESTS

Solution S

Dissolve 1.000 g in carbon dioxide-free water R with heating, allow to cool and dilute to 100.0 mL with the same solvent.

Appearance of solution

Solution S is clear (2.2.1).

pH (2.2.3)

5.0 to 8.0.

To 10 mL of solution S add 0.1 mL of a saturated solution of potassium chloride R.

Reducing sugars

Maximum 0.2 per cent.

Test solution: To 1 mL of solution S add 1 mL of cupri-tartaric solution R4. Heat on a water-bath for 10 min, cool to room temperature. Add 10 mL of ammonium molybdate reagent R1 and allow to stand for 15 min.

Reference solution: Prepare a reference solution at the same time and in the same manner as the test solution, using 1 mL of a 0.02 g/L solution of glucose R.

Measure the absorbance (2.2.25) of the test solution and the reference solution at the absorption maximum at 740 nm using water R as the compensation liquid. The absorbance of the test solution is not greater than that of the reference solution.

Light-absorbing impurities

Examine solution S between 230 nm and 750 nm. Between 230 nm and 350 nm, the absorbance (2.2.25) is not greater than 0.10. Between 350 nm and 750 nm, the absorbance (2.2.25) is not greater than 0.05.

Related substances

Liquid chromatography (2.2.29).

Test solution (a): Dissolve 0.250 g of the substance to be examined in water R with heating, cool and dilute to 25.0 mL with the same solvent.

Test solution (b): Dilute 5.0 mL of test solution (a) to 50.0 mL with water R.

Reference solution (a): Dissolve 25.0 mg of alfadex CRS (impurity A), 25.0 mg of gammacyclodextrin CRS (impurity B) and 50.0 mg of betadex CRS in water R, then dilute to 50.0 mL with the same solvent.

Reference solution (b): Dilute 5.0 mL of reference solution (a) to 100.0 mL with water R.

Reference solution (c): Dissolve 25.0 mg of betadex CRS in water R and dilute to 25.0 mL with the same solvent.

Column:

— size: l = 0.25 m, Ø = 4.6 mm;

— stationary phase: end-capped octadecylsilyl silica gel for chromatography R (5 μm).

Mobile phase: methanol R, water for chromatography R (10:90 V/V).

Flow rate: 1.5 mL/min.

Detection: Differential refractometer.

Equilibration: With the mobile phase for about 3 h.

Injection: 50 μL of test solution (a) and reference solutions (a) and (b).

Run time: 2 times the retention time of betadex.

Identification of impurities: Use the chromatogram obtained with reference solution (a) to identify the peaks due to impurities A and B.

Relative retention: With reference to betadex (retention time = about 10 min): impurity B = about 0.4; impurity A = about 0.6.

System suitability: Reference solution (a):

— resolution: minimum 1.5 between the peaks due to impurities B and A; if necessary, adjust the concentration of methanol in the mobile phase.

Calculation of percentage contents:

— for impurities A and B, use the concentration of the corresponding impurity in reference solution (b);

— for impurities other than A and B, use the concentration of betadex in reference solution (b).

Limits:

— impurities A, B: for each impurity, maximum 0.25 per cent;

— sum of impurities other than A and B: maximum 0.5 per cent;

— reporting threshold: 0.15 per cent.

Residual solvents

Head-space gas chromatography (2.2.28): use the standard additions method.

Internal standard: ethylene chloride R.

Stock solution A: To 20 μL of ethylene chloride R add 0.5 mL of dimethyl sulfoxide R and dilute to 25.0 mL with water R.

Stock solution B: To 25 μL of trichloroethylene R add 25 μL of toluene R and 0.5 mL of dimethyl sulfoxide R, then dilute to 50.0 mL with water R.

Test solutions (a), (b), (c) and (d): In each of 4 identical vials, introduce 0.5 g of the substance to be examined, 0.10 g of calcium chloride R, 30 μL of α-amylase solution R and 1 mL of reference solutions (a), (b), (c) and (d), respectively, then add 9.0 mL of water R. Prepare test solutions (b), (c) and (d) in triplicate.

Reference solution (a): Dilute 250 μL of stock solution A to 10.0 mL with water R.

Reference solution (b): To 100 μL of stock solution B add 250 μL of stock solution A and dilute to 10.0 mL with water R.

Reference solution (c): To 200 μL of stock solution B add 250 μL of stock solution A and dilute to 10.0 mL with water R.

Reference solution (d): To 300 μL of stock solution B add 250 μL of stock solution A and dilute to 10.0 mL with water R.

Blank solution: In a vial identical to those used for the test solutions, introduce 0.10 g of calcium chloride R, 30 μL of α- amylase solution R, 0.5 mL of dimethyl sulfoxide R and 10.0 mL of water R.

Column:

— material: fused silica;

— size: l = 25 m, Ø = 0.32 mm;

— stationary phase: macrogol 20 000 R (film thickness 1 μm).

Carrier gas: helium for chromatography R.

Flow rate: 1.7 mL/min.

Static head-space conditions that may be used: if the equipment has different setting parameters, adjust the equipment settings so as to comply with the system suitability criterion:

— equilibration temperature: 45 °C;

— equilibration time: 2 h;

— syringe temperature: 50 °C;

— injection speed: 500 μL/s.

Temperature:

— column: 50 °C;

— injection port: 140 °C;

— detector: 280 °C.

Detection: Flame ionisation.

Injection: 200 μL.

Relative retention: With reference to the internal standard (retention time = about 13 min): trichloroethylene = about 0.6; toluene = about 0.8.

System suitability: Test solutions (b), (c) and (d):

— repeatability: maximum relative standard deviations of the ratios of the areas of the peaks due to trichloroethylene and toluene to that of the peak due to ethylene chloride of 10.0 per cent, for each set of triplicate test solutions and each residual solvent.

Calculate the content of trichloroethylene and of toluene taking their relative densities to be 1.46 and 0.87, respectively.

Limits:

— trichloroethylene: maximum 10 ppm;

— toluene: maximum 10 ppm.

Loss on drying (2.2.32)

Maximum 16.0 per cent, determined on 1.000 g by drying in an oven at 120 °C for 2 h.

Sulfated ash (2.4.14)

Maximum 0.1 per cent, determined on 1.0 g.

ASSAY

Liquid chromatography (2.2.29) as described in the test for related substances with the following modifications.

Injection: Test solution (b) and reference solutions (a) and (c).

System suitability: Reference solution (a):

— repeatability: maximum relative standard deviation of 2.0 per cent for the area of the peak due to betadex, determined on 5 injections.

Calculate the percentage content of [C6H10O5]7 using the chromatogram obtained with reference solution (c) and taking into account the assigned content of betadex CRS.

STORAGE

In an airtight container.

IMPURITIES

Specified impurities A, B.

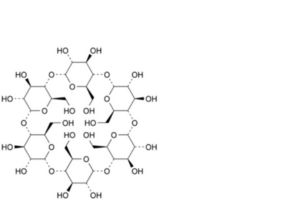

A. cyclohexakis-(1→4)-(α-D-glucopyranosyl) (alfadex, cyclomaltohexaose, α-cyclodextrin),

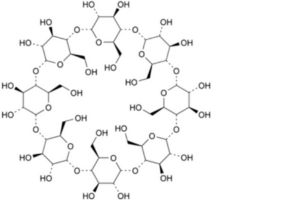

B. cyclooctakis-(1→4)-(α-D-glucopyranosyl) (gammadex, cyclomaltooctaose, γ-cyclodextrin).